Sliding Into a Robotic Frontier

- James Post is an engineer for NASA’s Marshall Space Flight Center and a mentor for a team of students, Redstone Robotics, building a robot to compete in the FIRST Robotics Competition.

- James contacted Accuride and asked if the company would consider supplying a pair of 9301 Heavy-Duty slides. Within a few days of the request, Accuride shipped out a pair of 9301 slides to Redstone Robotics.

- James and his students used the Accuride 9301E, a heavy-duty non-disconnect slide that supports loads up to 600 lbs. and 42″ wide, and comes in variable lengths up to 60″. These slides are commonly found in industrial racks, large tool carts, and service vehicles.

We’ve seen plenty of innovative uses for ball-bearing slides. But James Post and his class may have set a new bar.

“James Post is an engineer for NASA’s Marshall Space Flight Center, handling instrumentation in Alabama. He’s also a mentor for science students at New Century Technology High School in Huntsville. Their team, Redstone Robotics, counts a dozen students and five mentors.

While Redstone Robotics’ students and mentors had embarked creative projects before, their latest was the most unique yet: A robot. And not just a robot, but a robot that would compete in the FIRST Robotics Competition, or FRC for short.

(FIRST is also an acronym: For Inspiration and Recognition of Science and Technology. It’s an international non-profit organization that encourages student advancement in science.)

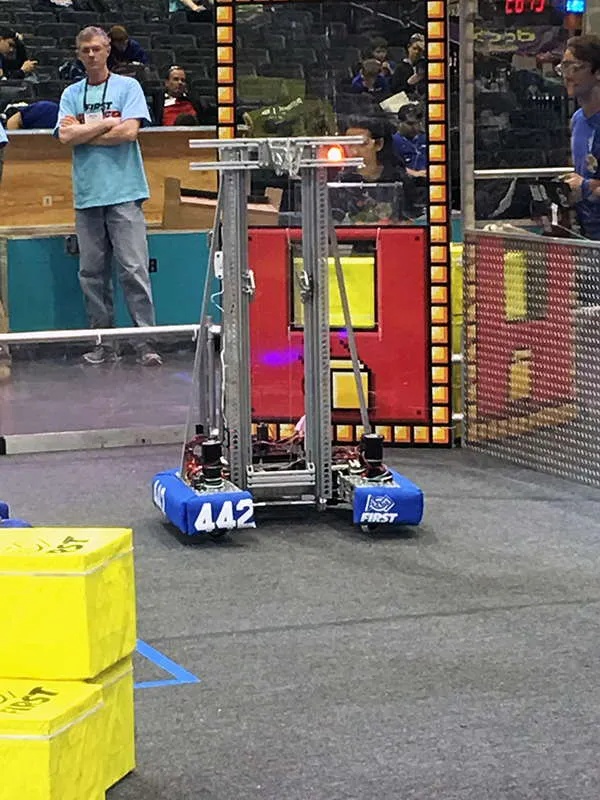

Affectionately nicknamed “Lieutenant Dan,” the team’s three-wheeled robot measures roughly 32 in. long, 28 in. wide, and up to 8 ft. all when the robot’s fully lifted (up from 4.5 ft. starting). The robot, remotely operated, is able to retrieve and deliver objects. “The key objective [of the competition],” James explains, “was to handle milk crates and place them in various targets.”

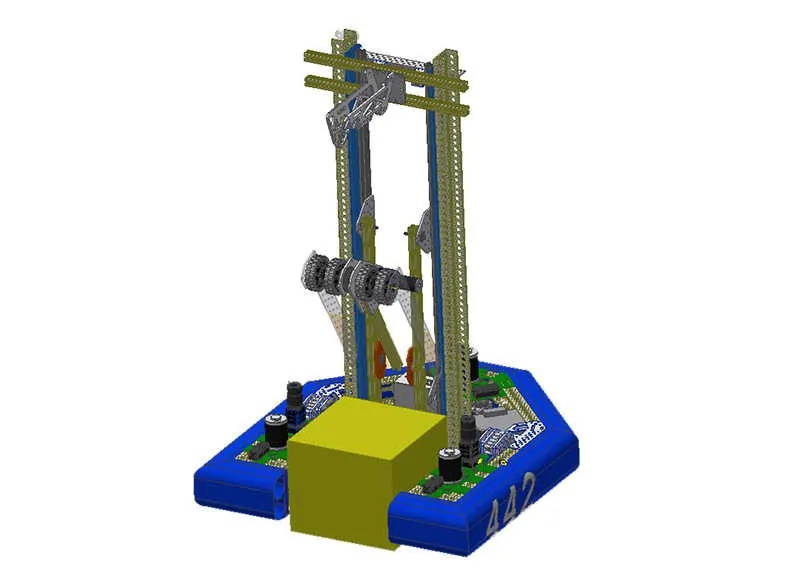

Above is a 3D model of the robot James and his class created for the FIRST Robotics Competition. Accuride 9301 slides allow the movement of the lifting system. You can see the Accuride slides in blue.

James and his students felt confident Lt. Dan could do all that, provided they had the hardware. A particular challenge arose when they needed a durable movement system for their robot’s lifting mechanism.

As James recalls: “We were in a predicament on how to insert a durable, cost-effective lifting mechanism. One of my senior students just came out and said, ‘Why don’t we toss in some four-foot Accurides?’”

There was just one problem: How could a small team of students, with almost no budget, afford a pair of premium-grade, four-foot slides?

Answer: Just ask!

James contacted Accuride and asked if the company would consider supplying a pair of 9301 Heavy-Duty slides. One look at the endeavor and the company had a resounding “YES!” Within a few days of the request, Accuride shipped out a pair of 9301 slides to Redstone Robotics.

The team found implementing the 9301 to their robot very simple. That was thanks to the Computer-Aided Designs (CADs) found on the product page. “Having the CAD model, along with an industry-standard hole-pattern, made integrating the 9301 a breeze.”

A photo of the robot in action. One can’t help but remember TV’s Robot Wars…

How much did Accuride’s 9300 help Lt. Dan and the team at Redstone Robotics? “Tremendously,” James says. “In fact, the final element of the competition was for the robot to lift itself. We focused much of our effort on that operation–and we were successful thanks to the Accuride 9300!”

James and his class are already planning for their next robot. Will Accuride be a part of that? “Absolutely,” says James. “This next one will likely be smaller and lighter. We’re looking at a heavy-duty slide, probably the 7900 Series, on this next robot. We’re excited about the possibilities!”

So is Accuride!

James and his students used the Accuride 9301E, a heavy-duty non-disconnect slide that supports loads up to 600 lbs. and 42″ wide, and comes in variable lengths up to 60″. These slides are commonly found in industrial racks, large tool carts, and service vehicles. You can find other models in the same family, including those with lock-in and lock-out features, by visiting the 9300 Series Page.

Related Posts

Accuride in Action: Holmberg Cases

June 5th, 2023

Accuride Heavy-Duty Movement for Ever-Demanding Industry

June 5th, 2023